What is progressive stamping of metals?

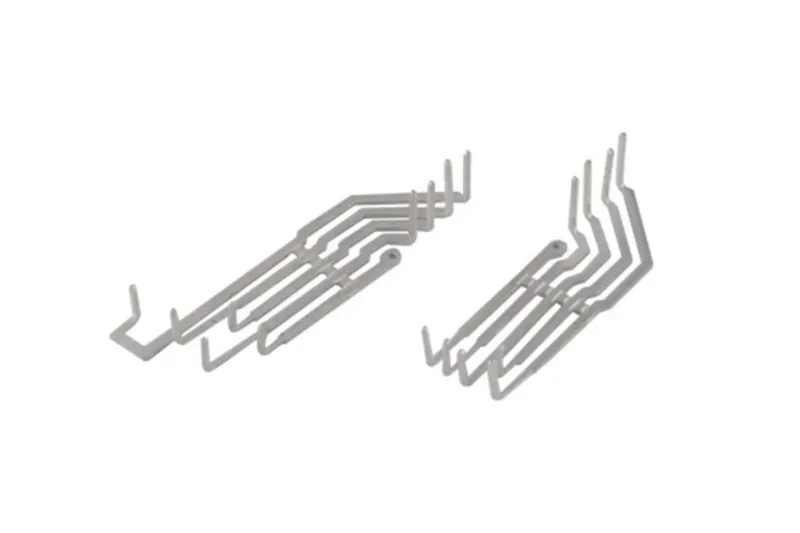

I see complex metal parts often fail to meet tight tolerances and large-scale production goals. I feel frustrated when traditional methods cost more time and money. I find progressive stamping provides a precise, high-volume solution that improves quality and efficiency. Progressive stamping of metals is a manufacturing process that employs a series of integrated dies […]