With more than 15 years of manufacturing experience in aluminum extrusion forming industry, we have a professional technology development and design team with rich experience and quality assurance.

Equipped with advanced 10 sets of extruder production lines, we have strong production strength.

We have established a perfect quality control system. Ensure that every piece of aluminum extrusion products delivered to customers meets or even exceeds industry standards and customer expectations.

We provide detailed loading report support for each shipment, so that customers can have a clear picture of the shipment, which is convenient for customers to carry out the subsequent goods receiving and management work.

The company provides customized solution services, professional technical team will communicate with customers in depth, tailored for customers one-stop aluminum extrusion solutions.

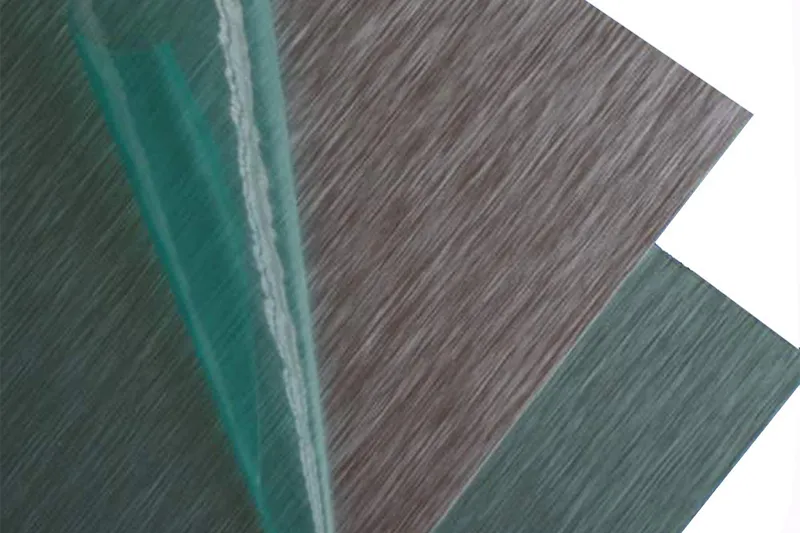

Strict testing of raw materials ensures that your aluminum profiles are made of 100% pure A00 aluminum ingots with no impurities and uniform composition.

Quality control personnel (QC) will randomly select the coated surfaces for inspection and to pass the salt spray test.

Using Atomic Emission Spectrometer (AES), the chemical composition of aluminum extruded products is analyzed. The content of aluminum and other alloying elements in the product can be detected quickly and accurately.

Through the fatigue testing machine, simulate the alternating load situation that the product may encounter in actual use, and during the test, record the stress-strain situation of the product under different cycle times until the product shows fatigue cracks or rupture.

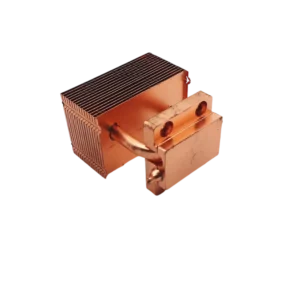

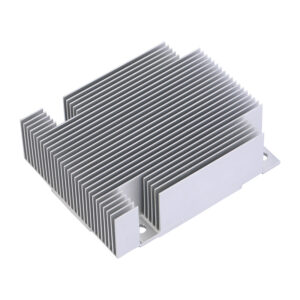

A wide range of aluminum profiles to meet your needs.

KAIYAN has become a leader in the aluminum extrusion industry by virtue of its superior technology and innovative ideas. We focus on providing high-quality and customized aluminum extrusion solutions to our global customers to meet the demanding needs of aluminum profiles in various industries. Since our establishment, we have accumulated many years of experience in aluminum extrusion manufacturing. KAIYAN is a global company with advanced aluminum extrusion production lines equipped with high-precision extrusion equipment and advanced die manufacturing technology.

At present, KAIYAN has developed into a professional supplier of industrial and architectural aluminum extrusion products, electronic and electrical products, and has constructed a whole set of aluminum alloy processing service system exclusively for AMAZING.

KAIYAN’s independent system control enables the aluminum extrusion equipment to produce different shapes of aluminum profiles, such as extruded aluminum round tubes, extruded aluminum square tubes aluminum round tubes, extruded aluminum profile beams, Z-profiles, extruded T-profiles, and so on.

1. Mold design capability: KAIYAN (KY) has a strong design engineering team with very rich experience in mold design and manufacturing.

2.Advanced production equipments: We have advanced production lines, 10 sets of imported extruders from Japan and Taiwan, including 800 tons, 3000 tons, 5000 tons and other large and small extruders.

3.High efficiency heating equipment

4.Powerful cooling system

5.Alloy material mixed extrusion

6.High precision welding process

7.CNC machining service

8.Product polishing

Specialized in aluminum extrusion research and development and production, with excellent technical team

With professional technical team and rich practical experience, we are able to successfully extrude various complex shapes of aluminum profiles.

Producing more than 6000+ different kinds of aluminum extrusion profiles every year

Diversified types of moulds, with a large number of standardized moulds, which can save your mould cost.

Producing more than 10,000 tons per year, no matter what time it is, we can deliver for you quickly.

Most of the machines used by KAIYAN (KY) are imported from Japan and Taiwan, which guarantee the quality of your products.

The aluminum alloy materials we choose are all of high quality and undergo strict quality sampling and composition testing. At the same time, we are also equipped with advanced testing equipment, such as spectral analyzers to test the composition of materials, and carry out comprehensive testing of finished products, so that only those products that meet the quality standards will be shipped out of the factory.

It depends on the specific shape and requirements of the particular product, but in general, we are able to control the dimensional tolerance between ±0.1mm – ±0.5mm, and for special products with very high precision requirements, we can reduce the tolerance to within ±0.05mm.

1. CAD file formats (DWG and DXF)

2. 3D model data exchange formats (IGES and STEP)

3.Common Document Format (PDF)

1. Provide KAIYAN with some product dimensions, shapes, etc. It is best to provide product design drawings.

2.Provide your product requirement quantity and your expected delivery time.

3.KAIYAN will communicate with you about the design, explain the design ideas and technical points, and both sides will communicate repeatedly until the final design is finalized.

We can extrude many alloy materials in the market, such as:

6061 aluminum alloy

6063 aluminum alloy

7075 Aluminum

1050 Pure Aluminum

1060 pure aluminum

2024 aluminum alloy

5052 aluminum alloy

The surface treatment process of our products is diversified, including anodizing, electrophoretic coating, powder coating and so on.

Which payment methods does KAIYAN accept?

1.Prepayment

2.Installment payment

3.Credit payment

4.Cash payment

Our company packs aluminum extrusion profiles in many different ways, there are the following packing methods:

1.Paper packing

2.Shrink wrapping

3.Protective film packaging

4.Wooden packaging

5.Combination packaging

1.Channel aluminum

2.Square tube

3.Round tube

4.I-beam aluminum

5.Angle aluminum

Translated with DeepL.com (free version)

Copyright 2024 © Dongguan KAIYAN