Stamping Processing

Support copper, iron, aluminum, stainless steel and other metal materials processing

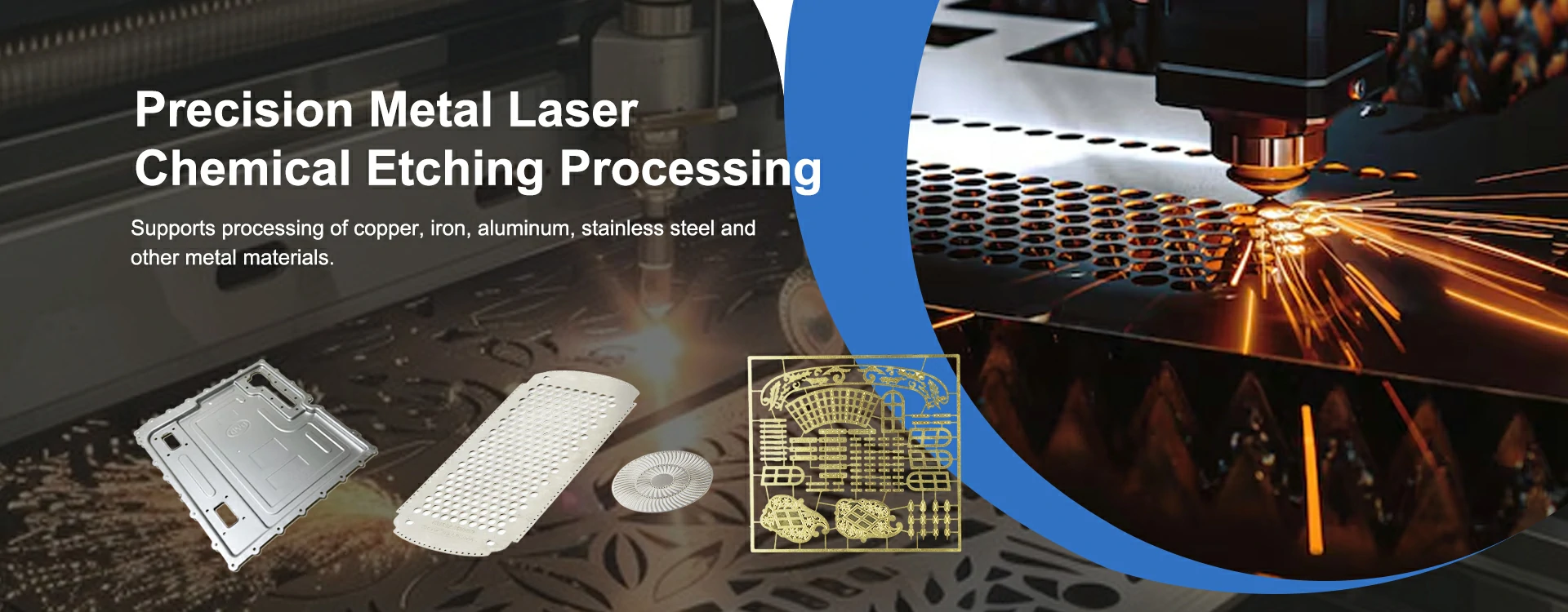

Chemical Etching Processing

Supports processing of copper, iron, aluminum, stainless steel and other metal materials.

According to the customer's drawings and samples, to provide customers with acomplete set of solutions and services

Own factory · Fast delivery

20 years of experience instamping industry, focusing on all kinds of stamping parts processing and customization.

According to the customer's drawings and samples, to provide customers with acomplete set of solutions and services

Our Manufacturing Capabilities

KAIYAN provides a range of manufacturing capabilities to support rapid prototyping and both low and high-volume production needs. With our own factory and a reliable Chinese network, we deliver complex, high-quality parts efficiently.

Professional manufacturer dedicated to customizing precision stamping parts

Founded in 2008, Dongguan Kaiyan Hardware Products Co., Ltd. is a manufacturing enterprise specializing in precision metal stamping. Its main products include: new energy vehicle battery, LED power shell, aluminum panel, chassis, bracket, shovel tooth radiator / piece electronic RF shield, socket spring contact piece, drawing piece, structure piece, terminal, home appliance parts and toys, etc Product. It can provide a complete set of services from product development, mold design and manufacturing, stamping processing, finished product assembly, Etching inspection and packaging, customs declaration to transportation,In order to fully meet the market demand and the quality demand of customers at home and abroad, the company has introduced a batch of imported testing equipment, such as 2.5-dimensional, projector, salt spray tester, electrodeposition thickness testing instrument, micro Vickers hardness tester, Rockwell hardness tester, surface roughness measuring instrument, height gauge and micrometer card.

Trusted By Over 1K+ Companies

What We Offer

-

Metal Stamping Parts – Rivets

Read more -

Metal Stamping Services – Contact Spring

Read more -

Aluminum stamping – Controller Chassis

Read more -

All Metal Stamping – Controller Chassis

Read more -

Power Supply housing

Read more -

U-Shaped Nut

Read more -

U-Shaped Nut

Read more -

U-Shaped Nut

Read more -

U-Shaped Nut

Read more -

U-Shaped Nut

Read more -

PCB Terminal

Read more -

Crimp Terminal

Read more

More Benefits Of Working With Us

Industries We Serve

Medical

Medical

New Energy

New Energy

Satellite Communication

Satellite Communication

Automotive

Automotive

Aerospace

Aerospace

Electronics

Home Appliances

What Our Valuable Clients Say About Us

Latest News

Stamping Process FAQs: 20 Questions Engineers Ask Most

The metal stamping process is a high-speed, cost-effective manufacturing method for producing large quantities of identical metal parts by pressing or punching sheet metal with a die. This process involves various techniques, including blanking, bending, coining, and flanging, to shape a flat metal sheet into a desired form. For engineers, understanding the nuances of stamping […]

Top 10 Stamping Manufacturers You Should Know (With Comparison Table)

The top 10 stamping manufacturers you should know include global automotive giants like Gestamp and Magna International, high-precision specialists such as Kenmode and Wiegel Tool Works, and press technology leaders like Schuler AG. Choosing the right partner is critical for ensuring product quality, supply chain efficiency, and cost-effectiveness. This guide provides a comprehensive overview of […]

How to Select the Right Stamping Supplier (Checklist + Questions to Ask)

Selecting the right stamping supplier is a critical decision that directly impacts your product quality, production timeline, and bottom line. The ideal partner does more than just produce parts; they offer engineering expertise, ensure rigorous quality control, and function as an extension of your team. This guide provides a comprehensive framework for choosing a metal […]